Patient Specific Oxygen Masks

Medical Study

Imperial College London, 2016

Sleep apnea is a common condition that causes

windpipe closure during sleep. Treatment involves supplying air

via an

oxygen mask, using generalised masks

– causing

a

poor fit for most.

The resulting

leakage and

discomfort reduces

therapy

effectiveness.

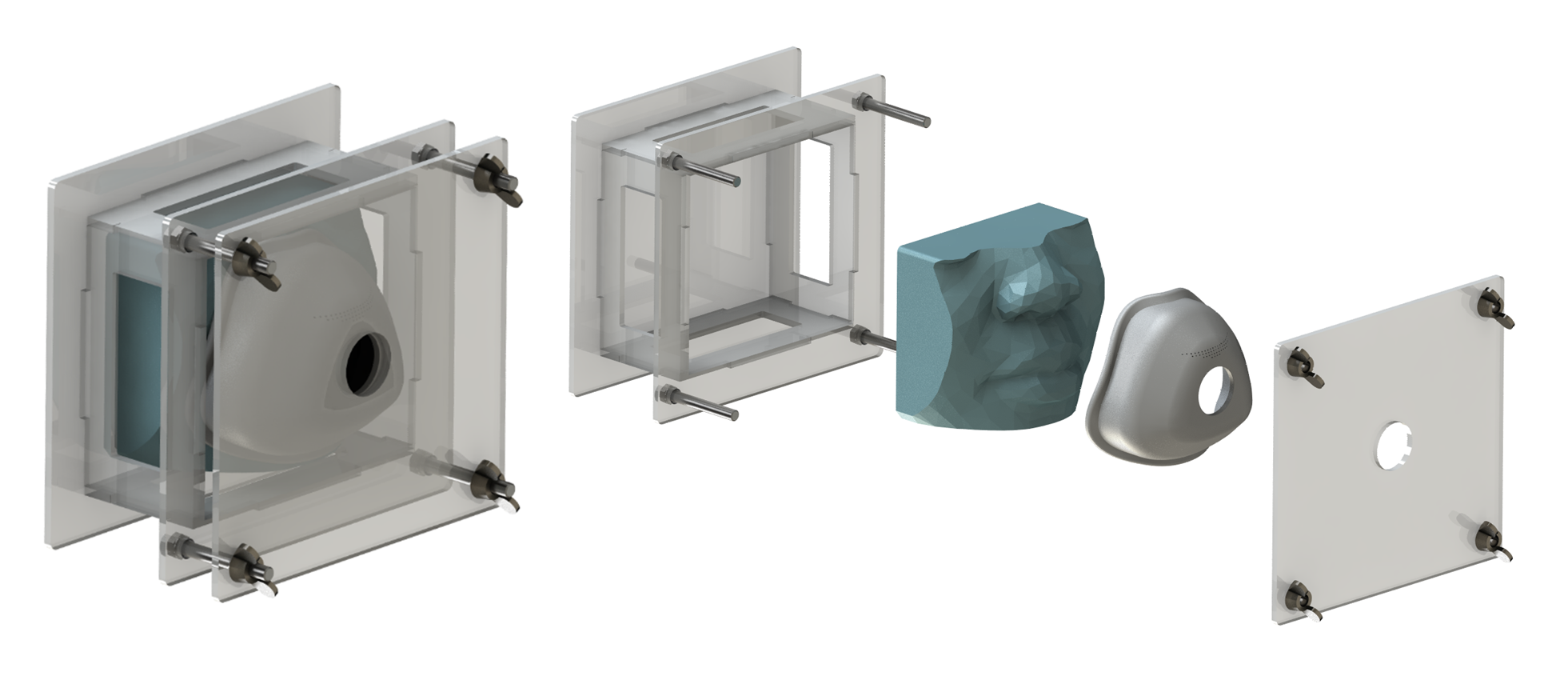

Specific silicon masks can be made via

an injection mould and CNC

machinery. Such methods

aren’t

economical however, and so are only used

within academia. The aim of the study was to develop

a workflow for

the rapid

manufacture

of patient-specific oxygen masks, and to validate their performance.

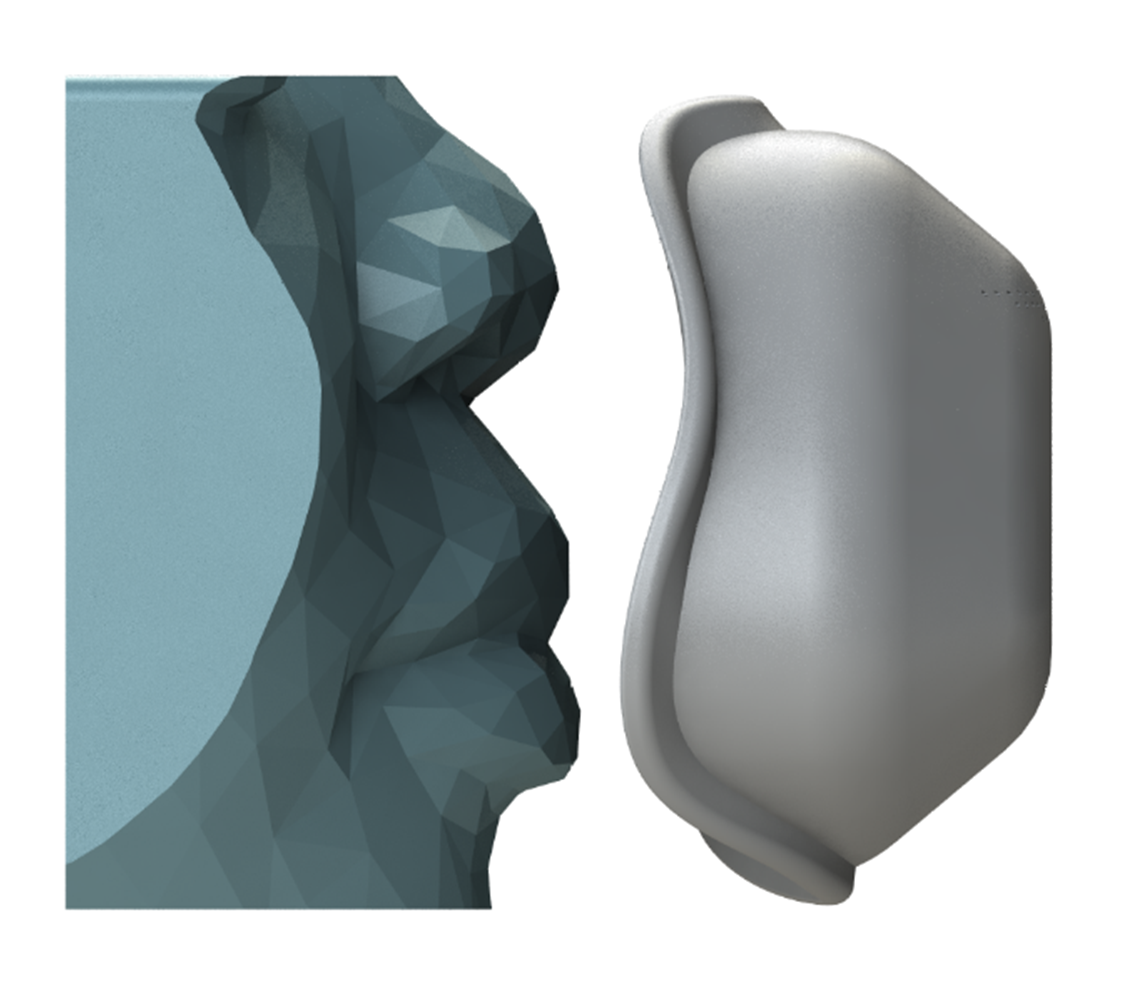

To test this, 3 different head scans were selected from a database,

for validation across a range of facial structures. Masks

shaped to fit each were then made

using

Fusion 360.

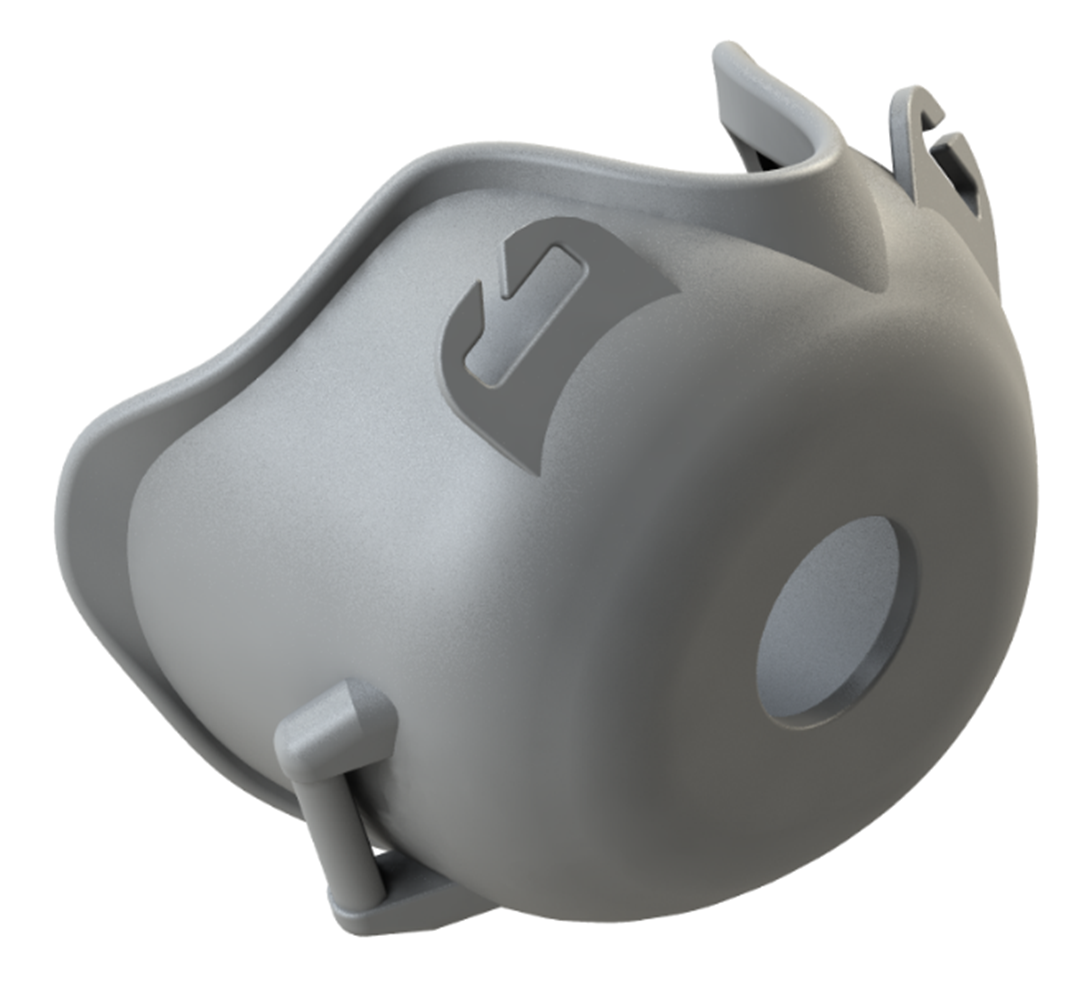

By making a patient-specific

mask, the compliance

of a

silicon mask wasn’t required to reduce leakage. Instead, the validated masks

were redesigned to be entirely 3D printed – significantly improving the

price-to-performance ratio. A laser-cut foam lining was integrated for patient

comfort.

![]()

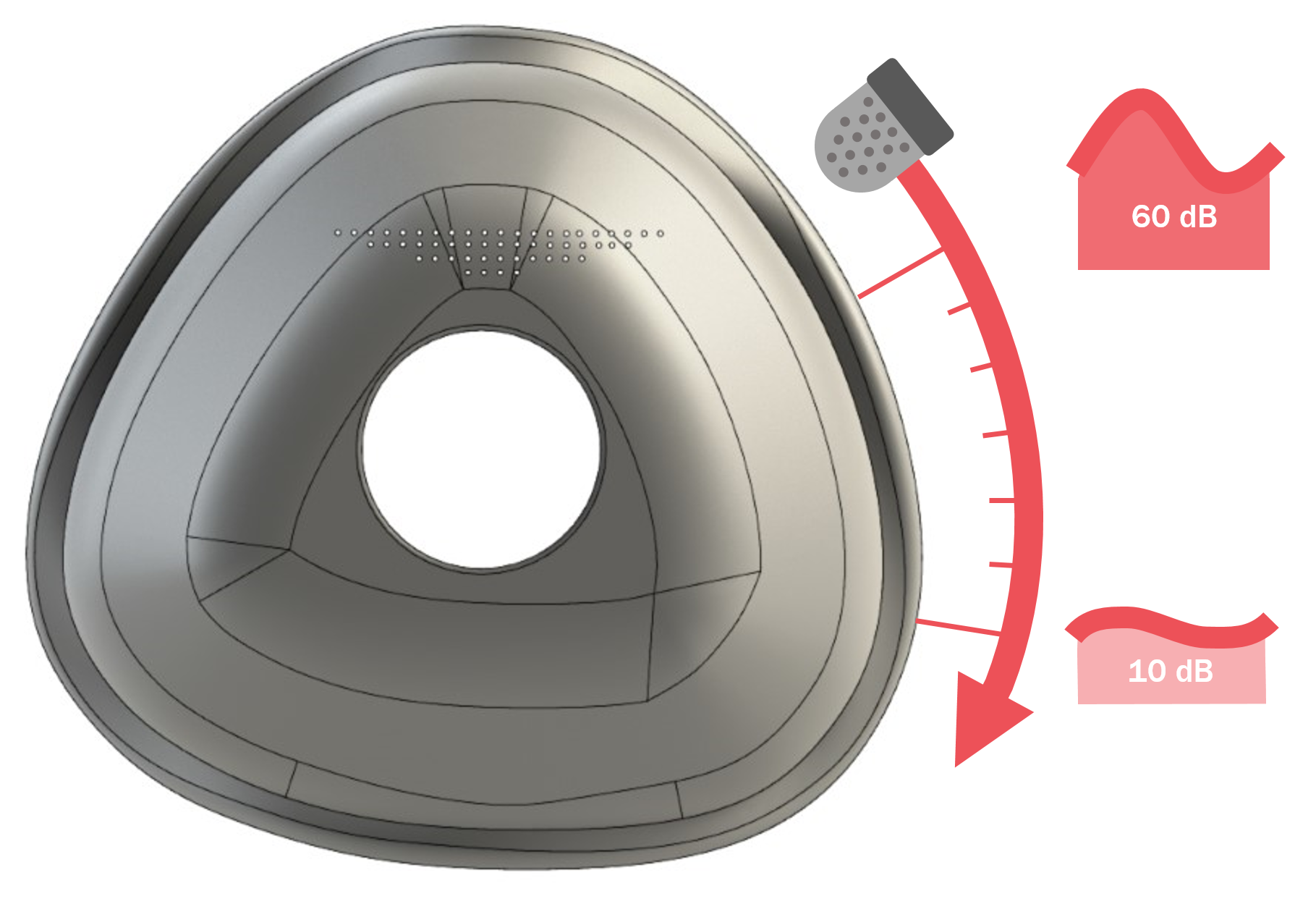

After experimenting with underwater and foam techniques, I developed an acoustic method to

measure leakage: a microphone was run across the mask-face interface, with the

response used as a measure of leakage. This showed leakage magnitude and

location – more informative than

conventional methods which just provide the total leakage flow rate.

The results confirmed the improved leakage

performance, and were showcased at the Imperial College Additive Manufacturing

conference. Additionally, it formed the basis of an ongoing PhD programme that’s developing the concept further.

Riyadh Rateme 2018 — London, UK

![]()

![]()

![]() By making a patient-specific

mask, the compliance

of a

silicon mask wasn’t required to reduce leakage. Instead, the validated masks

were redesigned to be entirely 3D printed – significantly improving the

price-to-performance ratio. A laser-cut foam lining was integrated for patient

comfort.

By making a patient-specific

mask, the compliance

of a

silicon mask wasn’t required to reduce leakage. Instead, the validated masks

were redesigned to be entirely 3D printed – significantly improving the

price-to-performance ratio. A laser-cut foam lining was integrated for patient

comfort.

![]()

![]()

![]()

![]()

![]() After experimenting with underwater and foam techniques, I developed an acoustic method to

measure leakage: a microphone was run across the mask-face interface, with the

response used as a measure of leakage. This showed leakage magnitude and

location – more informative than

conventional methods which just provide the total leakage flow rate.

After experimenting with underwater and foam techniques, I developed an acoustic method to

measure leakage: a microphone was run across the mask-face interface, with the

response used as a measure of leakage. This showed leakage magnitude and

location – more informative than

conventional methods which just provide the total leakage flow rate.